Keywords: SLS 3D printing materials, nylon powder parameters, tensile modulus, elongation at break, impact strength, KSPA12HP, KSPA12GB, PA12, PA11, Additive materials

We know that 3D printing requires different materials, among which SLS printing requires powder materials, the most common of which are PA12 and PA11. Faced with the complex parameters listed in the material parameter table, you may be a little overwhelmed. Today, I will briefly introduce the meaning of the commonly used parameters in the nylon powder parameter table.

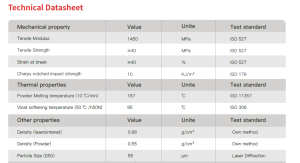

(Datasheet Example)

First, there are tensile modulus and tensile strength, both of which reflect the tensile resistance of printed parts. The tensile modulus mainly reflects the relationship between the force and deformation of the material. Generally, the larger the value, the more difficult the material is to be stretched. For example, Kings’ self-produced powder KSPA12GB has a tensile modulus of 3000Mpa due to the addition of glass fiber. The conventional PA12 and PA11 have a tensile modulus of only about 1500Mpa. Tensile strength indicates the tensile value of the material. The larger the value, the stronger its tensile resistance. For parts that need to be stressed, these two points need to be considered.

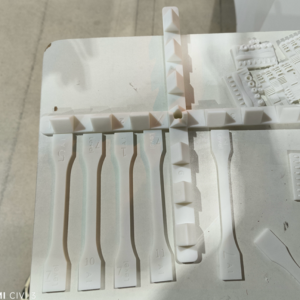

(PA12 Printed Sample)

Next is the elongation at break, which indicates the deformation of the part from the force to the fracture. It can be simply considered that the larger the elongation at break, the stronger its deformation ability and the more flexible it is. This parameter needs to be taken into consideration when printing products that need to be assembled. For example, buckles, screw holes, slots, robot fixtures, and other parts that need to be deformed. Among them, Kings’ KSPA12HP has this parameter of more than 40%, which is much greater than conventional PA12 or PA2200, similar to PA11 or PA1101, but the cost is much lower than PA11.

Another important performance parameter is Charpy (notched) impact strength, which indicates the impact resistance of the material. The larger the value, the better the impact resistance. This parameter is particularly important for printing some functional parts, especially those that may be impacted during use. No one wants the replacement parts to be damaged in a few days. For conventional PA12, its impact resistance is usually 4-6 KJ/㎡, and PA11 can reach about 7-8KJ/㎡. Kings’ KSPA12HP has shown excellent performance in this regard, with an impact strength of 10 KJ/㎡.

In addition to the above mechanical parameters, powder materials also have particle size parameters, temperature parameters, density parameters, etc., which will affect the performance of the device during printing. We will discuss this next time.

Author: Jerry